SCOPE OF ACTIVITY

The production activities of MARKOS Production mainly include custom engineering manufacturing in the following areas of production:

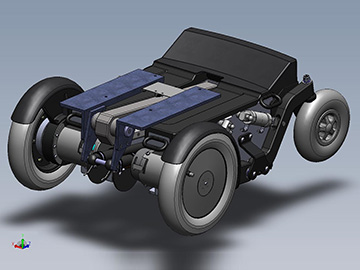

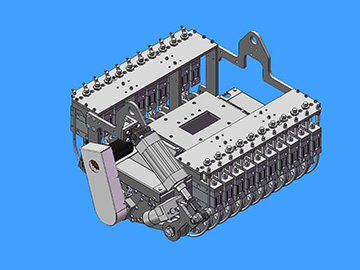

- Production and assembly of functional sets of machines and equipment

- Production of single-purpose or multi-purpose machines for various industrial branches

- Prototype production and testing of machines and various devices for various purposes and industrial applications

- Production of turning, welding, measuring and assembly preparations according to the client’s requirements as well as our own designs

- Production of individual mechanical components

- Production of steel constructions and weldments

- Production of pressure and non-pressure vessels

- Production of special trailers, semi-trailers and bodies for trucks

- Complete overhauls and machine restoration

The scope of our activity in the individual projects is solely defined by the client. However, we can provide all the stages within an independent solution of a project of a machine component, equipment or the entire machine:

- Conceptual solution design in 2D/3D

- Detailed solution design in 2D/3D

- Implementation and production documentation in 2D/3D

- Production of the prototype and its testing

- Updating documentation according to the test results

- Activation and optimization of production costs (piece/series)

- Production management and planning according to the actual and current requirements of the client

- Storage, logistics and the possibility of “just-in-time” deliveries